In-House Production

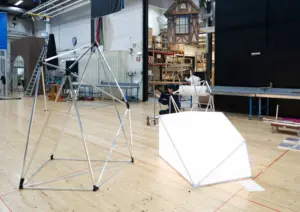

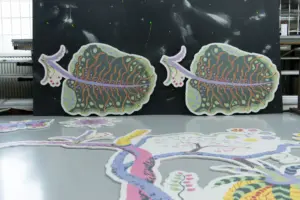

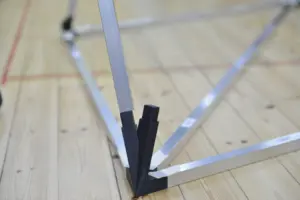

Hands-on production services are developed within our in-house production environment, covering carpentry, and aluminum construction as well as in-house 3D printing for objects and molds. Each service is adapted to the scale, function, and visual requirements of the project.

Below, we walk through each workshop capability and how it is applied in different production contexts.