LAB / R&D

Innovation never stops. Our Big Lab continuously explores new materials, constructions, and sustainable inks — testing, refining, and reimagining what’s possible.

Every creation finds its own way — guided by imagination, collaboration, and craft.

We invite you to one of our studios for a guided tour, material inspiration, and a deep dive into what’s possible, from innovative textures to sustainable production methods.

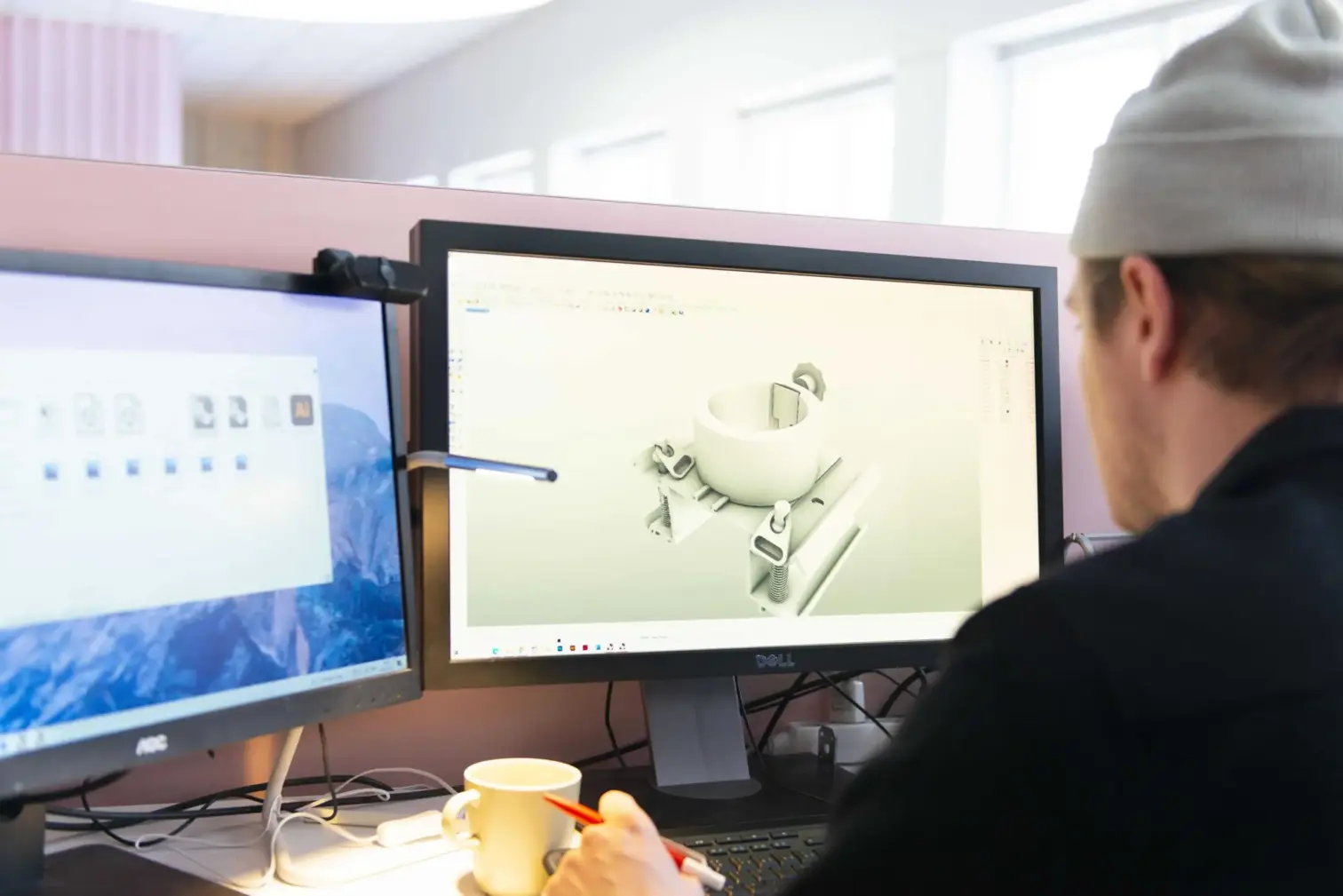

Through renderings we help creatives refine their vision before production begins.

You’ll have a dedicated project manager by your side, coordinating everything from research and safety certifications to permits, subcontractors, and sustainability advice.

Complex projects run smoothly through tailored order systems, advanced logistics, and international customs handling. This process is supported by our custom platform, Big Image Flow.

Big LAB enables early testing, prototyping, and material development for projects that require more than standard production, allowing ideas to be refined before they are built at full scale.

Through tailor-made digital tools and apps, we build systems that simplify complex processes related to orders, production, or deliveries.

With custom-trained AI Image Models, we create tailored solutions for advanced visual workflows. From retail and product imagery to film, television, and large-scale visual production.

With the support of AI and traditional methods, we can create artwork from scratch, develop or adapt your artwork, enhance existing visuals, or prepare images for large-scale production. A craft we’re at the forefront of.

From antique carpets to vintage posters, digital capture ensures accurate reproduction for archival documentation, film use, and creative projects.

We can refine every detail, adjust colors, enhance textures, and perfect compositions to bring out the best in every visual.

Our high-resolution scanning transforms artworks into digital artworks, ready to be preserved or reimagined into new creative expressions.

Ahead of production, test prints, color matching, prototype assembly and technical checks are carried out in the studio. are used to confirm the right result. This ensures the material and method are right before the final print run.

From soft textiles and recycled fabrics to hard materials and specialty foils. We print on nearly anything, including our signature cotton images up to approximately 12×50 metres.

Our craftspeople handle everything from hems and tunnels to advanced shaping, hidden eyelets, and complex fabric solutions.

Precision cutting, contour shaping, and unique formats give your visuals architectural presence.

We build circular, cubic, and freestanding structures — welded, rolled and lacquered — sometimes combined with acoustic or light-integrated design.

From classic lightboxes to dynamic, programmable systems, we design custom lighting in any shape, temperature, and size — controlled via Casambi, Plejd, or your preferred system.

For short-term installations or touring events, we offer rental of lightboxes, inflatable décor, screens, and projection equipment.

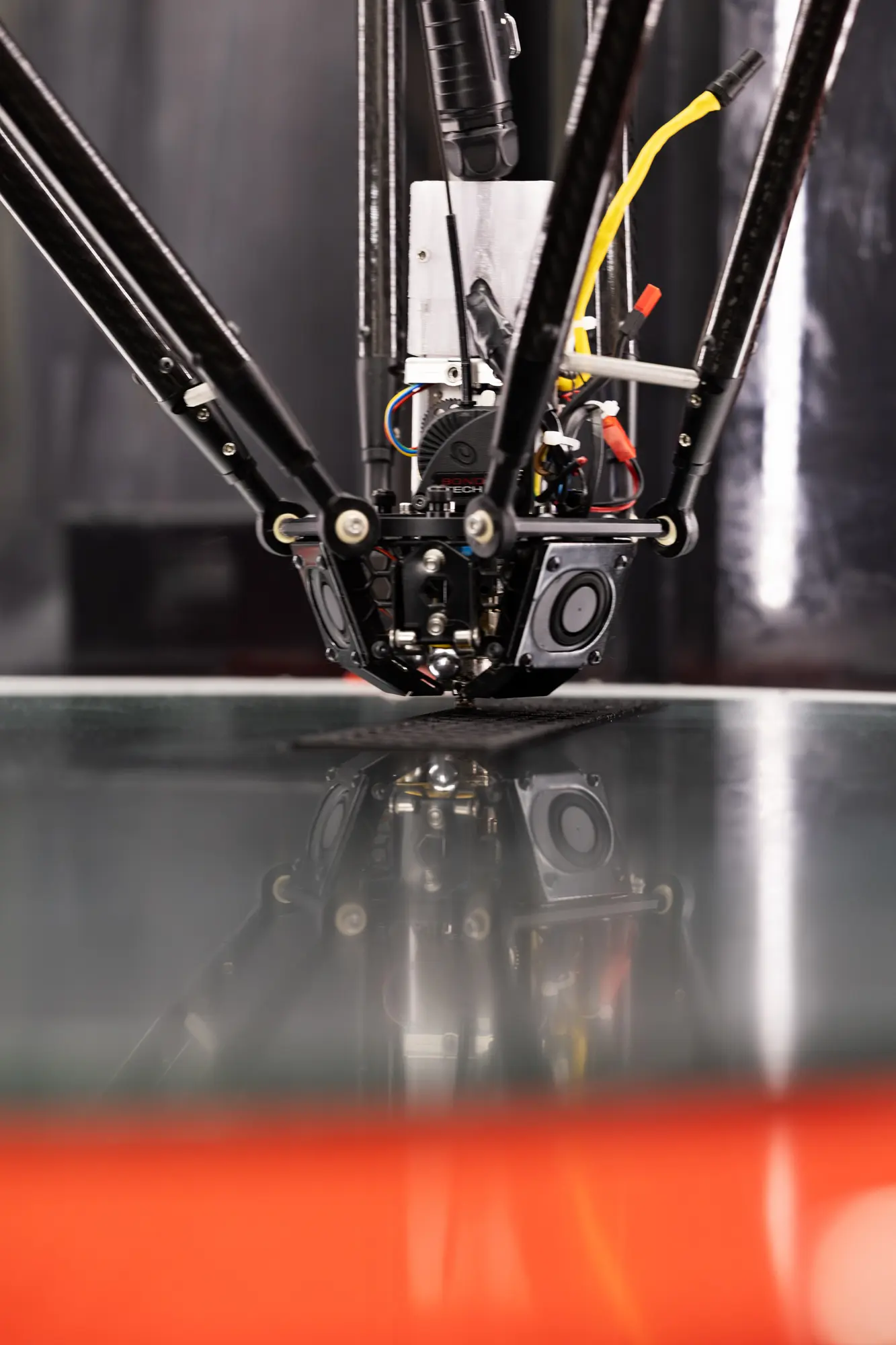

Home to the largest 3D printer in the Nordics, we produce large-scale objects with a wide range of filaments and finishing options.

After printing, test installation can be carried out before delivery. We also offer full-scale test installation on our BeMatrix wall for productions ordered with BeMatrix.

Our workshop handles the full production of custom constructions and props. We work with wood, metal, and composite materials, using both manual craftmanship and machine-based processes.

We work with large-scale LED setups, projection mapping, and interactive elements to turn surfaces into moving visual displays. With a long background in scenography and printing, we combine physical materials with digital layers to create environments.

We provide detailed sewing and construction drawings, coordination with subcontractors, and easy-to-follow video guides for a seamless setup.

Each delivery is packed and tracked with precision — using image-based packing slips, GPS tracking when needed, and sustainable packaging designed for reuse and reduced impact.

Our project managers and installation leaders are available on location or on call 24/7, ensuring perfect assembly and documentation — complete with final photography and film.

We assist with dismantling, transport, and material reuse whenever possible — because sustainability doesn’t stop at delivery.

Every Big Image project is designed, produced, and finished in our own studios — ensuring quality, control, and responsibility at every step.

Innovation never stops. Our Big Lab continuously explores new materials, constructions, and sustainable inks — testing, refining, and reimagining what’s possible.

Partner up with us and we’ll provide the tools, expertise, and guidance to bring your idea to life.